HomeRobotic Database - Robotic platform | TERRINet

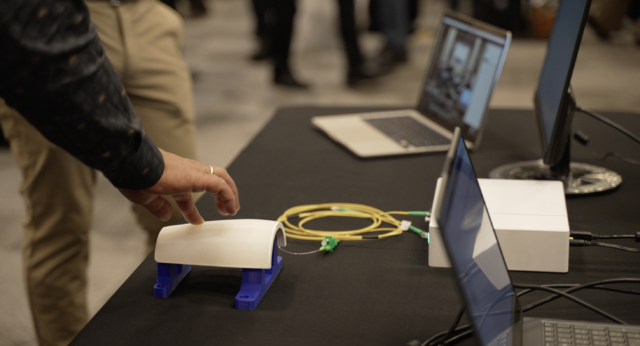

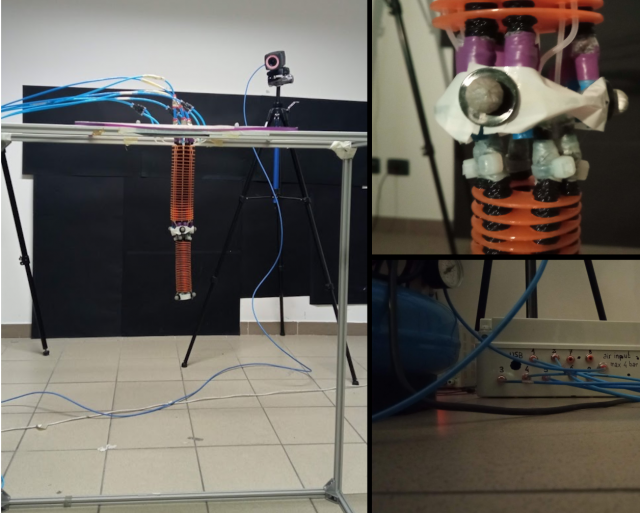

STIFF-FLOP soft manipulator

Modular soft manipulator with high dexterity and intrinsic safety. The manipulator is based on a modular approach and each module is 60 mm long and 14 mm in diameter. It is able to implement omnidirectional bending and elongation when pressurized (pressure range: 0 – 1.5 bar).The basic version of the manipulator is composed of two modules, completely based on elastomers (silicones) and some ABS parts for connection. On the tip, the system can lodge a micro camera, a gripper or an ablator (all tested)

Key features:

- Safe interaction with body parts or delicate objects

- Modular

- Contraction, elongation, omnidirectional bending

- Multipurpose platform

Possible applications:

- Endoscopic/Surgical robotics

- Controllable overtube structure for inserting and guiding flexible tools

- Soft robotic platform for testing control algorithms

Technical specifications

| Modules can be quickly connected/disconnected for a one/two modules manipulator.: | |

| DoF: | Infinite passive – 6 active (actuators) |

| Time response (pneumatic valves): | 0.03 sec |

| Interface: | USB |

| Power supply: | 220 V@ 50 Hz |

| Weight: | 9 g (per single module) |

| Operating pressure: | 0 – 1.5 bar (per single fluidic chamber) |

| Bending: | Omnidirectional – max 90 deg |

| Elongation: | 50% |

Access information

| Corresponding infrastructure | School of Advanced Studies Sant'Anna The BioRobotics Institute |

| Location | Viale Rinaldo Piaggio, 34 |

| Unit of access | Working day |

Access history

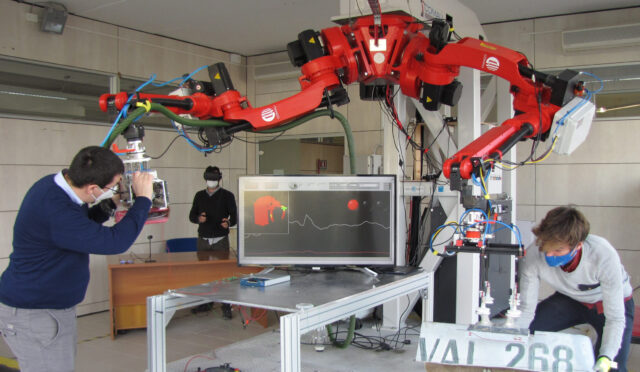

The STIFF-FLOP Algorithm Exchange - Testing of Position Controller of a Novel Growing Soft Robot

Burcu Seyido?lu

The proposed study was to implement the control algorithm of a novel growing soft robot to the STIFF-FLOP soft manipulator. The project objectives are listed below:

• Enhancing the end-effector’s position accuracy by using novel growing soft robot’s algorithm which includes deformation correction

• The consideration of external loads applied to the end-effector, which affect tip positioning.

• Increasing the overall performance of the tip positioning by exchanging the algorithms.

• Making the overall position information of the end-effector more precise, accurate, and robust.

There are three possible impacts of the proposed study. Firstly, the proposed development in the algorithm and a successful algorithm exchange can increase the tip positioning of the STIFF-FLOP and thus improve its applications in the new areas of use. Secondly, it can also affect the future applications of the novel growing soft robot developed by home institution, by increasing its accuracy and robustness, and thus increase its use especially in the surgical robotic applications. Finally, in the long-term, it can draw attention to this field and lead to new technological improvements and solutions.