HomeRobotic Database - Robotic platform | TERRINet

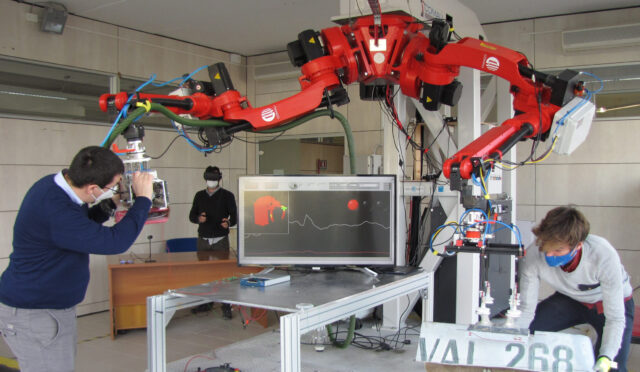

Robotic arms: KUKA LBR4+

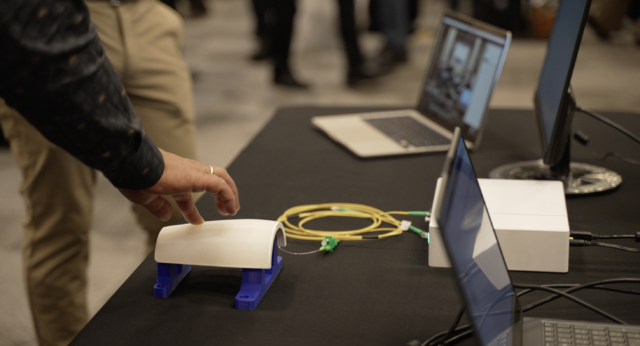

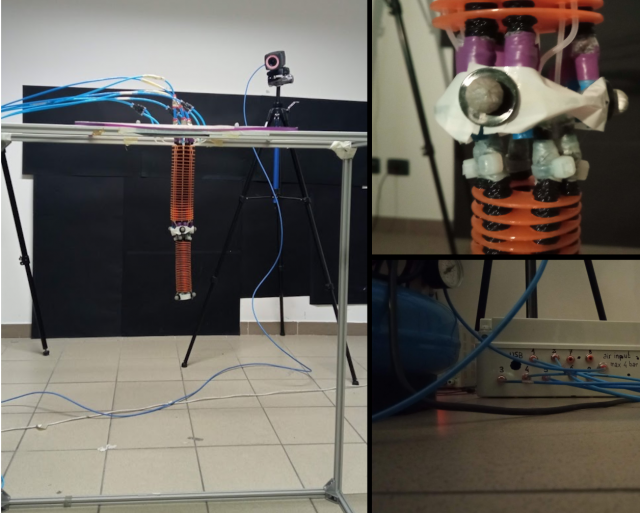

At RaM we have multiple general-purpose robotic arms; KUKA LBR4+ arm and Franka Emika Panda arms. Each is a 7-axis fully-actuated robot with torque sensing and control. Each joint is equipped with a position sensor on the input side and position and torque sensors on the output side. The robots can thus be operated with position, velocity and torque control.Unlike typical factory robots, which are so dangerous they are often put inside cages, these arms can operate among people. They are designed to perform tasks that require direct physical contact in a carefully controlled manner. These include drilling, screwing, and buffing, as well as a variety of inspection and assembly tasks that electronics manufacturers in particular have long wanted to automate. The KUKA robot is programmable in C++.The Franka Emika robots are setup with Robotic Operating System (ROS) interface, hence they may be programmed in a variety of languages such as C++, Python, etc.

Key features:

- 7kg load capacity;

- Since it is a collaborative robot, its sensors detect external forces made by an obstacle or a human.

- Weight of 16 kg;

- Can be programmed by moving it by hand;

- Workspace range 790mm;

- Its rounded shape contains no sharp edges that could be harmful to a human working beside it;

Possible applications:

- Learning by demonstration and reinforcement learning of manipulation tasks;

- Implementation of control algorithms for industrial and medical manipulation tasks;

- Development of eye-in-hand visual servoing algorithms;

- Inspection and service robotic applications;

- Medical applications such as control of an ultrasound transducer to follow in-body instruments such as a catheters, endoscopes or biopsy needles.

- Testing teleoperation algorithms;

- Physical human-robot collaboration and interaction tasks;

Technical specifications

| Number of axes: | 7 |

| Volume of working envelope: | 1.84 m3 |

| Repeatability (ISO 9283): | ±0.05 mm |

| Weight approx: | 16 kg |

Access information

| Corresponding infrastructure | University of Twente Department of Robotics |

| Location | Hallenweg 15, |

| Unit of access | Working day |