HomeRobotic Database - Single Infrastructure | TERRINet

Address:

Coldharbour Ln, Stoke Gifford,

Bristol BS16 1QY, UK

Website

http://www.brl.ac.uk/rifbristol/roboticsinnovationfacility.aspx

Scientific Responsible

Chris Melhuish

About

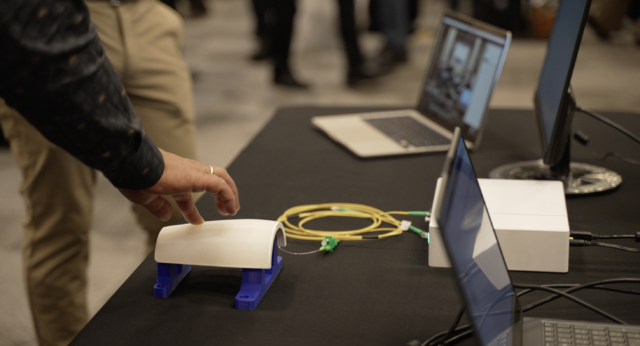

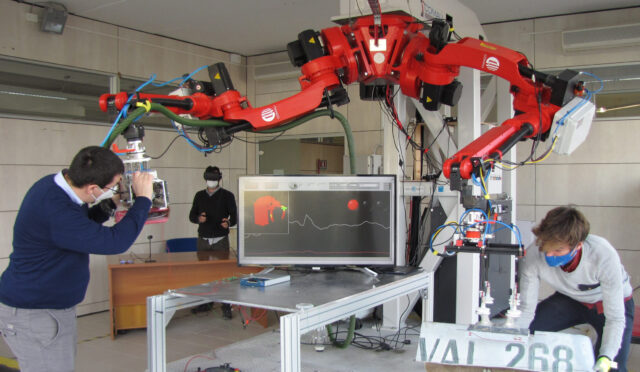

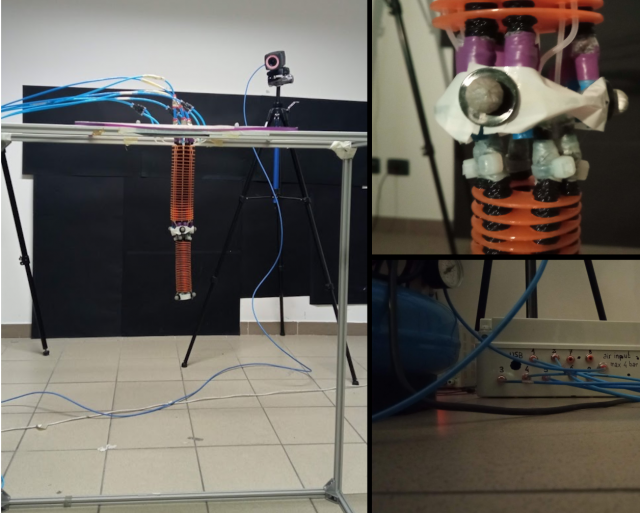

The Robotics Innovation Facility (RIF) is a European funded programme that brings researchers and industry in direct contact with current and new users of robotic technologies. RIFs are open to the public labs, which provide state-of-the-art robotic hardware and software, as well as scientific and technical support. Anticipating market trends, the RIFs cover a wide range of application areas. Located within BRL, the RIF@Bristol covers an area of circa 100 m2 and is equipped with a number of robots, vision systems and other items of automation. Three dedicated personnel service the RIF and support its offerings with additional assistance provided by the BRL technical support team and other engineers and scientists employed in the laboratory as and when required. The Bristol RIF will provide access to equipment and expertise to assist with:

- Estimating and analysing market size for new products, services or a processes

- Design of novel end-effectors and sensors

- Proof of concept demonstrations in novel robot application areas

- Integration of robotic systems in manufacturing, health, training, entertainment etc.

- Human/machine interface and robot programing

- Requirement analysis and concept demonstration in the field of Assisted Living and Medical Robotics

- Application and demonstration of robotics in agriculture, horticulture and food production

Available platforms

ABB IRB 14000 YuMi

Collaborative, dual-arm robot. The robot includes integrated collision detection, lead-through mode, force-sensing parallel grippers, integrated camera-based part location and synchronized arm motion control. It presents over actuated arms (additional external link) for easy repositioning, alternative configurations and object avoidance. Flexible and safe to work with, without the need of cage or additional safety systems. High repeatability and speed, limited load capacity. Tool flange presents 24V, 1 A power supply, with Ethernet communication protocol. Alternative solutions (serial or custom) are available for different end-effectors.

Rethink Robotics Baxter

Collaborative, compliant dual-arm robot. Power and force limited by design, with series elastic actuators and torque sensors. The robot includes integrated collision detection, lead-through mode, parallel grippers and integrated vision. It presents over actuated arms (additional external link) for easy repositioning, alternative configurations and object avoidance. Flexible and safe to work with, without the need of cage or additional safety systems.

KUKA KR60-3

Six-axis industrial grade robot arm. Flexible and versatile, with high repeatability, medium load capacity and high speed, high duty cycles. EtherCAT communication (Industrial Ethernet), Profisafe, Backhoff 32/32 digital I/Os at 24 VDC and 4-channel outputs at 24 VDC, 2 A.

Universal Robots UR5

Lightweight, flexible collaborative robot. The robot includes freedrive mode, force-sensing for collision detection and several wide spread end of arm tooling. Flexible and safe to work with, without the need of cage or additional safety systems. High repeatability and speed, quick to program. Tool flange presents 12V/24V, 600 mA power supply, with Ethernet communication protocol. Alternative solutions (serial or custom) are available for different end-effectors. 2/2 Digital I/Os and 2 Analog inputs.